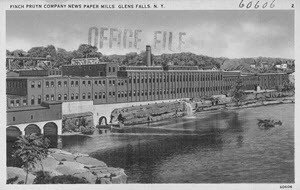

Finch Pruyn Paper Mill

Did you work at Finch Pruyn Paper Mill? Diagnosed with Mesothelioma or Lung Cancer?

You may be entitled to receive compensation. Mesothelioma and lung cancer victims & their families have been awarded over $1 million+ from easy access to funds. Call us today to apply.

Over the past 20 years, we've helped 1,000s of families claim the compensation they deserve with no upfront costs to them.

Shortcuts to common asbestos exposure: