Corning Glass Works

You may be entitled to receive compensation. Mesothelioma and lung cancer victims & their families have been awarded over $1 million+ from easy access to funds. Call us today to apply.

Over the past 20 years, we've helped 1,000s of families claim the compensation they deserve with no upfront costs to them.

For over 150 years, the city of Corning, New York has served as the namesake and operational headquarters of the multinational glass-and-ceramics manufacturer, Corning Incorporated – formerly known as Corning Glass Works. Corning Glass Works made extensive use of asbestos materials and equipment in their factories and job sites, which exposed workers to airborne asbestos fibers.

The company was a major employer in the city of Corning and the Southern Tier New York community at large. Asbestos use at Corning Glass Works has resulted in cases of mesothelioma and other diseases developing in former employees of the company.

Belluck & Fox, LLP has represented many clients who developed mesothelioma because of on-the-job exposure to asbestos. Prior to the 1980s, asbestos was a widely used material in industry and construction.

While it was known to the asbestos producers that mesothelioma and other diseases resulted from asbestos exposure, the companies chose to not warn the public. This resulted in thousands of illnesses and deaths, and over 3000 people are still being diagnosed with mesothelioma every year. We are very familiar with the companies that made and sold asbestos products, and can help mesothelioma victims find the justice they deserve.

Corning Glass Works Mesothelioma Trust Fund & Lawsuits

Table of Contents

Mesothelioma and lung cancer victims are qualified for the following Asbestos bankruptcy trust claims if they worked at Corning Glass (Corning): A-Best, AP Green, Babcock & Wilcox, Combustion Engineering, Eagle Picher, Fibreboard, Harbison Walker, Owens Corning.

Asbestos Exposure at Corning Glass Works Corning, NY

Founded in Somerville, MA, as the Bay State Glass Company in 1851, the company chose to relocate to Steuben County, New York in 1863. Following the move, it shed its previous moniker and adopted the name Corning in honor of its new home city.

Corning Glass Works’ labor needs expanded rapidly as the demand for the company’s products increased over the course of the twentieth century. Hundreds of workers in Steuben County were employed at Corning during this time, most at the company’s local manufacturing plants and research facilities.

Unfortunately for these workers, equipment at Corning Glass Work factories and research centers prior to the 1980s utilized asbestos parts. Asbestos could be found in equipment such as boilers, turbines, pumps, valves, lehrs, other furnaces, and tanks. The company also used asbestos materials such as tape, insulation, gaskets, packing, and drywall. As a result, many workers who were employed at Corning Glass Work during this time have been diagnosed with mesothelioma and other asbestos illnesses.

The law firm Belluck & Fox, LLP has represented retired workers who were exposed to asbestos at Corning Glass Works’ facilities during this era. These clients, diagnosed with mesothelioma, went on to win significant settlements for the pain and suffering they endured.

The Corning Glass Work manufacturing complex was one of the company’s original production facilities, constructed mainly along the Chemung River. The layout of this production and research operation was not centralized; rather, the company maintained a distributed network of sites throughout Corning and the neighboring areas of Painted Post, Horseheads, Erwin, and Big Flats.

Each site was responsible for a particular purpose, but workers would sometimes be required to transfer between these sites based on the needs of the particular day. Each of the sites used asbestos.

The main campus consisted of a large building segmented into three distinct work areas, referred to as the A, B, and C factories. This plant served as a central dispatch for laborers at Corning Glass Works’ Corning-area facilities. Workers also spent time on production at the site, where they focused on the production of hand-blown glass products.

These factories contained many specialized furnaces for annealing glass, known as Lehrs. Annealing is a process by which glass is cooled very slowly to prevent stress fractures and shattering. A Lehr is a furnace with a conveyer that moves new glass from a very hot temperature on one end to gradually lower temperatures at the other. These Lehrs were made using asbestos. When repair or maintenance was required, workers would scrape, wire brush, and often remove and re-apply the asbestos, releasing fibers into the air.

Asbestos tape and sheeting was also used in this facility. The tape had many applications throughout the plant such as sealing ductwork and patching. It was also very important to glassmaking because it was used to wrap the ends of tongs, which workers would use to move hot glass between machines. This tape would be soaked in a solution of water and Epsom salts, which would make it rigid, but brittle. The soaking and cutting processes would release fibers from the tape, and the brittle final product would flake off and release dust into the air.

A similar product was asbestos fabric that was stretched into sheets several feet in length, then soaked in water and Epsom salts and dried until rigid. This product shared the same dangers as asbestos tape, and was used throughout the various Corning Glass Works’ plants.

A Corning Glass Work Powerhouse stood a short distance from this complex, at the far north end of the campus. It generated steam and hot water from boilers, which used turbines to generate power for the plant. Boiler rooms and powerhouses at factories from this era contained a high density of asbestos products, due to the high temperatures and steam they generated. Pumps and valves located in the boiler space moved these high-temperature liquids and gasses throughout the plant, and used asbestos packing and gaskets to create seals.

Pipes were also coated with asbestos cement, which would come as a dry powder that needed to be mixed with water on-site. The process of mixing and applying the asbestos powder, often done by hand and without special gear, would fill the air with asbestos dust and make direct contact with workers’ skin, hair, and clothing. The companies that produced and sold these asbestos products were aware of the dangers of asbestos, yet offered no warning on their products.

Less than a mile away from the main A/B/C factories, a second campus existed with three additional facilities. The first, known as the Fallbrook plant, manufactured glass products for industrial applications, such as glass tubing. The site used machines called Danner and Vello machines to produce long, continuous glass tubes. These machines were essentially furnaces that extruded molten glass, meaning that they were heated to incredibly high temperatures. Asbestos was used on almost all industrial furnaces prior to the 1980s.

Asbestos-wrapped tongs were often used to handle the newly formed glass as it came out of these machines, and asbestos clothing, including heat gloves, was used to shield workers from the dangerously high temperatures. The manufacturers of these so-called “safety” products never mentioned that they were made of a substance that caused mesothelioma, asbestosis diagnosis and lung cancer, among other diseases.

Another plant at this campus was the Pressware plant, responsible for producing Corning Glass Works’ popular home kitchen products. These consumer products were made from proprietary Corning materials, such as Pyrex, Corningware, and Corelle, which required special production techniques that also involved high temperatures. Asbestos was used in similar ways to the previously-discussed buildings, including in the walls and roofing, in equipment and components, as refractory bricks, and as cement.

The last building on this campus was known as the Pilot Plant. Corning Glass Work, from very early in its history, utilized research and development to advance glass technology and bring new products to market. The Pilot plant was one of the company’s research and development sites, where the company conducted early experiments in television and other emerging technologies. The plant was insulated with asbestos, and many of the machines and equipment therein utilized the substance as well.

In the 1960s, Corning Glass Works built a larger research campus several miles to the west, known as Sullivan Park. Named for Dr. Eugene Sullivan, one of the most prominent engineers in the history of Corning Glass Works, the 400-acre campus was built as an investment in future technologies for the company to apply to its products.

In addition to where high heat was a concern, asbestos was also used where corrosive substances were a concern. Many different asbestos products were used at this facility, from protective clothing and asbestos tongs, to materials including asbestos insulation, drywall, and tile.

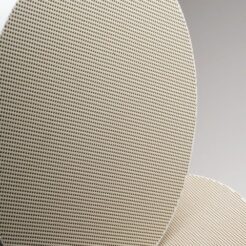

Several miles east of the main plant, Corning Glass Work operated a machining plant in the town of Big Flats. Here, workers were often exposed to asbestos dust from friction materials. Friction materials are rough, abrasive materials applied to surfaces to increase friction. Any sort of motorized machine in a factory of this type will have brakes attached to them, which need friction materials to properly slow and stop the machines.

Grinding wheels also used asbestos as a friction material. These wheels were used by skilled workers to shape formed glass. By their very nature, friction materials are constantly exposed to stress. The regular application of high heat and high friction these materials are exposed to means that as these products wear down, asbestos fibers are released into the air. Again, as in the other plants and facilities, asbestos could be found in many places in this factory, including insulation, fireproofing, gaskets, packing, pumps, and valves.

Further east, in nearby Horseheads, stood Corning Glass Works’ Holding Point Warehouse, used mainly for storage and shipping. Most of the asbestos at this location was related to building materials, leaving employees of contractors working construction jobs at the site especially at risk.

In June of 1972, the city of Corning was hit by Hurricane Agnes. The flood control systems of the time were not adequate to handle the volume of water dumped into the Chemung River. The result was widespread flooding throughout the city of Corning. The water not only damaged a great deal of product at Corning Glass Works’ local facilities, but it also damaged building materials and equipment that contained asbestos and stirred up a large amount of asbestos dust that had settled throughout the Corning plants.

The danger of asbestos is greatly increased when solid materials are damaged, as well as when asbestos dust is disturbed. This event created an especially hazardous situation in these facilities, and directly impacted workers tasked with cleaning and repairing the damage left in the wake of the flood.

Secondary exposure to asbestos, known as take-home exposure, would put the families of Corning Glass Works employees at risk. Asbestos fibers can settle on clothing, hair, shoes, and skin when loose in the air. When workers from the Corning plant ended their shifts, they would carry this asbestos dust on them, where it would release into the air of their own homes. Asbestos disease requires neither regular exposure nor exposure to large amounts of dust to develop. In some cases, asbestos disease has been traced to a single exposure.

If you have been diagnosed with mesothelioma or other asbestos-related disease, it is important to keep in mind that asbestos exposure does not happen by random chance. Asbestos was produced and used by companies that understood the threat these products posed and chose not to give the public warning. If you have an asbestos disease, it is likely that someone is responsible. While mesothelioma has no known cure, the attorneys at Belluck & Fox can help you find the justice you deserve.

Settlements from asbestos companies can pay for life-extending and quality-of-life treatments, and can provide for your family in their time of need. Our mesothelioma lawyers have represented clients who worked at the Corning Glass Works facilities mentioned above, and are very familiar with the sites and how people were exposed there. All kinds of workers were exposed to asbestos over the course of their Corning Glass Works careers, from workers on the labor gang to researchers and engineers.

There is no safe level of asbestos exposure, and it is likely that most workers at these Corning facilities were exposed to asbestos in some way prior to the 1980s.

Corporate History

Corning Incorporated has a long history of research and innovation in the glass and ceramics industry. Best known to consumers for developing glass and ceramic for use in kitchen products, such as Pyrex, Corelle, and Corningware, Corning was also instrumental in the development of technological milestones including the light bulb, the catalytic converter, manned space shuttles, and many other important products.

Research and development is a large part of Corning’s business, and the company has obtained hundreds of patents for the work of its researchers. Corning Incorporated no longer makes glass for consumer sale, having sold the rights to their Corningware, Corelle, and Pyrex lines to World Kitchens Incorporated. In the modern market, Corning has shifted their focus to technology, and develops new types of glass suited for use in applications such as LCD screens, modern space shuttles, and other devices.

Its line of scratch and crack resistant glass, Gorilla Glass, has become an industry standard for handheld devices such as phones and tablet computers, thanks in large part to Corning Incorporated’s close relationship with Apple Computers during the development of the original iPhone.

The company was originally founded by Amory Houghton, Sr. in 1851 as the Bay State Glass Company, headquartered in Somerville, Massachusetts. Several years later, the company relocated to northern Brooklyn, New York, where it was renamed the Brooklyn Flint Glass Works. In 1863, now under the leadership of Amory Houghton, Jr., the company was moved and renamed once more, settling into the city of Corning, NY, from which its current namesake is derived.

Corning Incorporated, then known as Corning Glass Works, has remained headquartered in the city of Corning ever since, and has continuously maintained strong ties to the city. In Corning, the company set up a large production complex, corporate offices, and a research and development facility. Though the locations and properties have changed over the years, Corning maintains its research, office, and production presences in Corning to this day. As of 2012, the company is listed as a global Fortune 500 venture, with offices and production facilities in countries including Russia, China, Taiwan, Korea, India, and Japan.

Over its history, Corning Incorporated has started a number of joint ventures and spinoff companies, often operating mostly independent of the parent company. These related companies include Dow Corning, Owens-Corning, Pittsburgh Corning, Corhart, Samsung Corning Precision Glass, Quest Diagnostics, and Covance.

Asbestos Manufacturing by Corning Businesses

The Corning family of companies has a long history of asbestos use. Several of these companies were well known as producers of asbestos products; most notably, Owens-Corning, Pittsburgh Corning, and Corhart.

Owens-Corning is a joint venture formed between Corning Glass Works and Owens-Illinois in 1935, with the goal of producing fiberglass wool and other types of insulation. By 1938, the company became a fully separate corporate entity from its parent companies, and found major success in the years following World War II.

Throughout the twentieth century, Owens-Corning produced several products made from asbestos. The company’s Kaylo brand of insulation, produced until the late 1970s, was its most widely distributed asbestos product.

It also produced insulating block, board, and panels under the Kaylo brand, as well as a line of asbestos cement known as One Kote. These asbestos products found wide use in both industrial and consumer markets, and never came with warnings or safe-handling instructions related to the dangers of asbestos. The popularity of Owens-Corning’s asbestos products led to countless asbestos exposures, in homeowners, laborers, contractor employees, Navy veterans, shipbuilders, plumbers, and laborers of all kinds.

Pittsburgh Corning was another Corning joint venture, this time formed between Corning and fellow glassmaker PPG Industries. The two companies came together to form the union in 1937, and began selling a line of asbestos insulation under the brand Unibestos in 1962. Unibestos was mainly sold for industrial use, and as the substance wore down, it exposed workers in many industries to airborne asbestos fibers. Workers were at risk of asbestos exposure from this product at paper mills, steel mills, chemical plants, factories, and power plants. Pittsburgh Corning sold this line of asbestos products until the 1970s.

Corhart, a joint venture beginning in the 1920s between Corning and Hartford Empire, was another joint venture responsible for the production and sale of asbestos products. Soon after it began, Corning Glass Works bought Hartford’s shares and rolled the Corhart line fully into its standard inline corporate structure. Corhart’s main asbestos products were refractories – bricks of asbestos meant for use in ovens, furnaces, and other applications involving extremely high temperatures. These bricks were even used at Corning’s factories, exposing their own workforce to the hazardous substances without ever warning their workers.

Corning Museum of Glass

1 Museum Way,

Corning, NY 14830

Belluck & Fox, LLP Helps Victims of Mesothelioma

Although it was known to be a harmful substance, the companies that made and sold asbestos products never warned the public the dangers of asbestos. Former employees of Corning Glass were likely exposed to asbestos on the job, and many have since developed mesothelioma. Settlements obtained by our firm can pay for treatment of the disease, and offer your family compensation to help them through a financially difficult time.

The key to a successful mesothelioma lawsuit is hiring attorneys who are familiar with asbestos cases. Belluck & Fox, LLP knows the asbestos manufacturers and the ways in which people were exposed to their products.

The attorneys at Belluck & Fox, LLP have won over $1 billion from businesses that sold asbestos products to consumers and industry, and have represented victims who were exposed to asbestos while working at IBM’s Endicott complex, including carpenters, technicians, tool makers, chemical analysts, insulators, and even field representatives.

We know the IBM site, and already have documents and research regarding the use of asbestos at IBM. We have also represented employees of contractors who have worked at the site, such as laborers and carpenters.

The recommended asbestos attorneys at Belluck & Fox, LLP know the strain that battling mesothelioma and other asbestos diseases can place on your life. Our New York mesothelioma lawyers can make accommodations to meet with you in your home, and will handle all the work on your case rather than referring you to another law firm.

There is no financial risk in retaining our services; we only receive payment if we recover money for you and your family. Our offices can be reached at 1-518-621-2699 or through our online contact form.

Additional Locations:

- 348 Sing Sing Road

Horseheads, NY - 792 Addison Road

Painted Post, NY - 890 Addison Road

Painted Post, NY

Associated Asbestos Occupations

- Engineers

- Laborers

Other Asbestos Companies in New York

- Dresser-Rand

- Ingersoll Rand

- Cornell University

- Chevrolet Buffalo Tarrytown

- Borg-Warner

- Foster Wheeler

- Chicago Pneumatic

- Crane Co.